Manufacturing industry veteran Al Alagarsamy shares a functional tip for sand production. He explains the importance of sand compactability and the factors affecting it.

What is the ideal range for compactability?

Compactability should ideally lie in the range of 36-42.

Why is it important?

It is important to control compactability of sand to produce good quality molds and castings. It affects sand fill and mold density in the pockets of pattern. It also affects the integrity of mold edges and corners.

How does compactability occur?

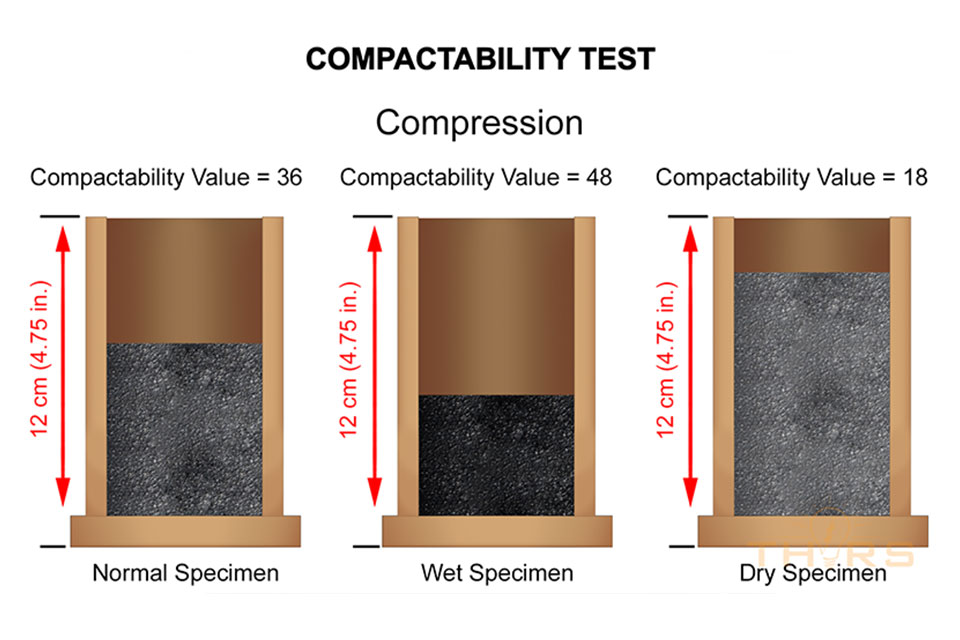

During mixing, water is absorbed between the clay platelets, clay swells and generates the ability of sand to be compacted. It is developed and controlled in the muller by the addition of water to the clay sand mixture. When expanded sand is compacted inside a confined space, the volume decreases and this is measured by reduction in the length.

Testing and reading compactability values for green sand samples

How does Compactability vary with Mulling time?

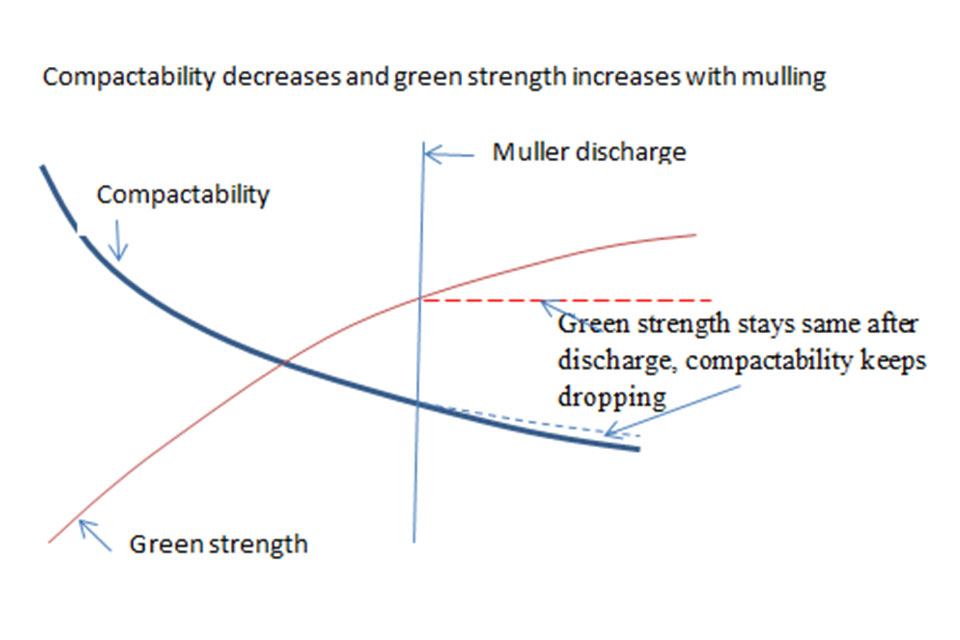

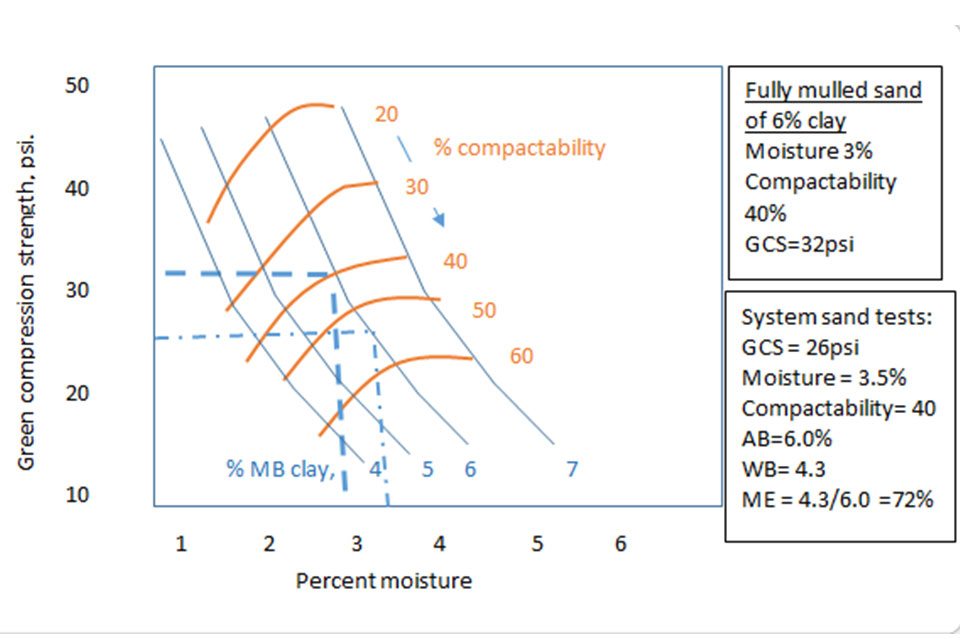

After water and bond are added to sand, the compactability quickly increases. As the mulling progresses, water is absorbed into the platelets and the compactability drops with increase in mulling time. Clay absorption does not stop after sand is discharged from the muller. This is different from green strength development with mulling time as shown in the graph below. Required compactability value at the muller is set to satisfy the limit established for the molding machine. This value is generally higher by 4 to 15 points at the muller.

Change in compactability and green strength with increase in mulling time.

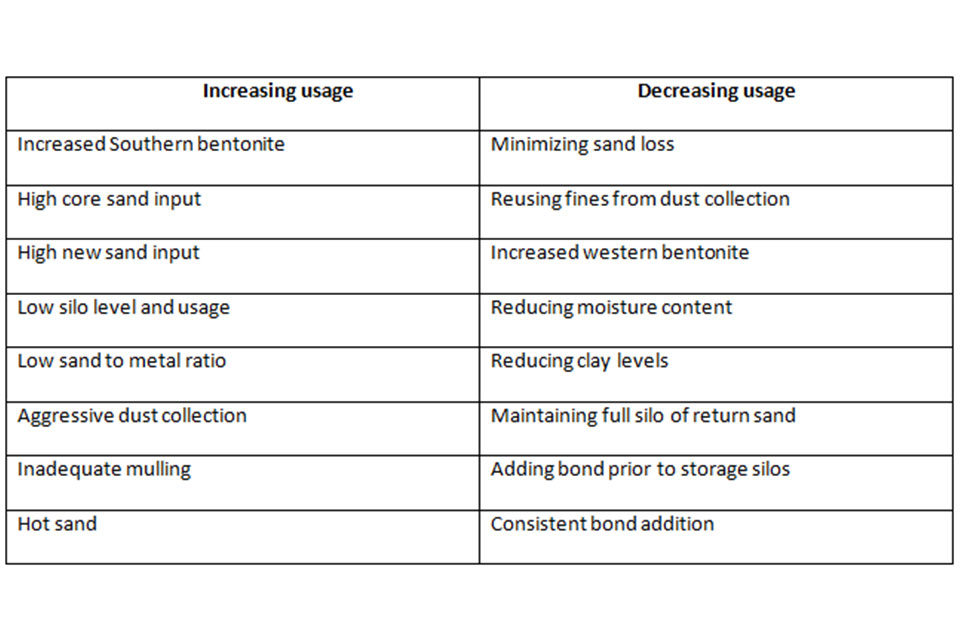

What are the factors that cause Compactability drop between the muller and the molding machine?

Depending on the sand system, there are two key reasons for the drop in compactability between the muller and the molding machine:

- Evaporation of moisture

- Continual absorption of moisture into the interior platelets of clay.

This month, let’s look into the factors that affect the evaporation of moisture from the mixed sand.

Factors affecting evaporation of moisture:

- Temperature of mixed sand

As the temperature gets above 115 F, moisture evaporates faster and correspondingly compactability decreases. - Number of transfer points

As the sand is transported from the muller to the molding machine, it travels through different belt conveyers to hoppers. Every time sand is transferred from one conveyor to another, it is exposed to ambient conditions. This exposure results in more evaporation and loss of moisture. - Aeration

As the term implies, aeration lets the sand mix with air. This results in reduction of moisture. - Ambient conditions

When ambient air is hot and dry, moisture evaporation is increased.

Watch this space to learn more about other factors affecting drop of controlling compactability of sand.

Interested in learning more about green sand, check out our course Green Sand Equipment and Process Control.