So what are the terms that describe the green sand clay level and how are they related to each other?

AFS clay, or 20 micron clay, or -20 micron clay

This process indicates the amount of fines and water absorbing materials in the sand system. Dried molding sand is dissolved in water, mixed vigorously for five minutes, and left to stand for another five minutes. After the heavier particles settle down, the top 5” of water is siphoned off. All the fine particles, including chemically active clay, carbons, and inert fines (less than 20 microns in size) will be suspended in water after five minutes of resting, and they are then removed through siphoning. This process is repeated until the water above the settled particles is clear and has no suspended particles. The remaining sand is then dried and the weight loss is expressed as a percent and recorded as AFS clay. A special apparatus, such as “rapid clay washer,” is generally used for this test.

AFS clay contains active clay, dead clay, coal dust, and other materials that float or dissolve in water. This test indicates the total water absorbing materials in the system. Out of all the materials, only the active clay part gives the sand bonding capacity.

Chemically active clay – Methylene Blue Clay

Methylene Blue (MB) clay tests measure the base-exchange capacity of Bentonite. The amount of exchangeable ions is determined by titrating against MB solution. Active clay that is capable of absorbing moisture develops strength when mixed in a muller. In this test, clay that is part of the dried sand from the system sand is dissolved in water with the aid of a Tetra Sodium Pyro Phosphate (TSPP) solution. This solution is titrated with methylene blue solution. When the end point is reached with a hallo, the amount of MB solution consumed is an indication of the amount of active clay present.

Clay that still has the capacity to exchange ions will contribute to green strength and dry properties. MB clay values depend on the type of clay, the purity of clay, and also depend on the skill of the technician. When standardizing the test procedure, a dried sample of Bentonite should be used and the moisture content of the testing material should be known and discounted. Incoming purchased materials may contain 8-10% moisture.

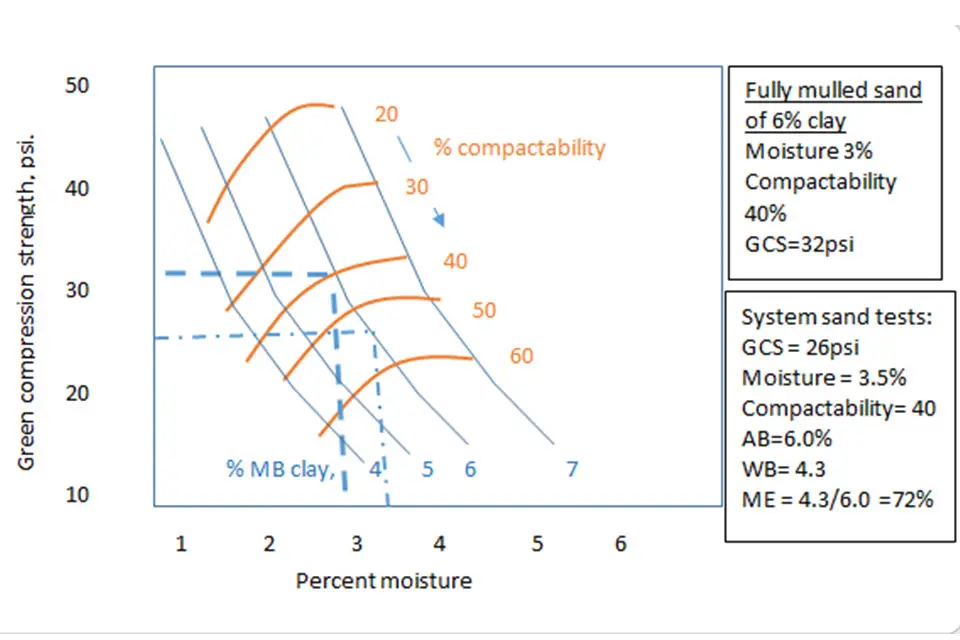

The terms Available Bond (AB) and Working Bond (WB) (or Active Clay) are used to describe the state of bond in the sand. These are called derived properties, meaning different test results (Green compression strength, compactability, and moisture) are used to determine the values. Reference charts developed from fully mulled sand mixed with new sand, clay, and water is used for estimating the values. These charts have GCS on the Y axis and moisture on the X axis, with lines representing clay levels and compactability drawn in. A simplified representation of the chart is shown above. It is helpful to know how these charts were developed to understand the meaning of AB and WB.

a. Available clay or Available bond (AB):

This value is calculated from green compression strength and the amount of moisture present to develop that green strength. Available bond indicates the presence of moisture absorbing materials, including active clay. The value is the MB clay value when fully mulled with that moisture yielding the green compression strength. AB estimation is affected by moisture absorbing materials in the system.

b. Working clay or Working Bond (WB):

This is derived from green compression strength and compactability. Working bond indicates the actual amount of clay that is producing the bonding strength. WB value is the MB clay value when it is mulled fully at that compactability.

c. Muller efficiency:

It is common to estimate the mulling efficiency using these two values. To obtain mulling efficiency, the working bond value is divided by the available bond value and expressed as a percent (ME = WB/ABx100). The higher the mulling efficiency, the greater the clay utilization. It should be noted here that 100% mulling efficiency does not result in good molding sand that will produce defect free castings.

The reference graph shown above depicts sodium bentonite fully mulled at different moisture levels. Different graphs for combination of different clays at higher levels and sea coal additions have been developed and published here*.

The derived properties very much depend on where the sample was taken in the system, as the compactability is changing from the muller to the point of use, along with moisture in the system as it evaporates during transport, thereby affecting the test results.

In a system, AFS clay will have the highest value, followed by the MB clay and available bond, which is then followed by the working bond. Exact values of clay will depend on the system, sand to metal ratio, fines, dust collection, and where the samples were obtained for the basic tests.

To learn more about green sand clay level, check out our course.

*T.S. Shih, R.W. Green, and R.W. Heine, Evaluation of 8-15% bentonite content of green sand properties. Part 4. Summary. AFS Transactions, 1987.