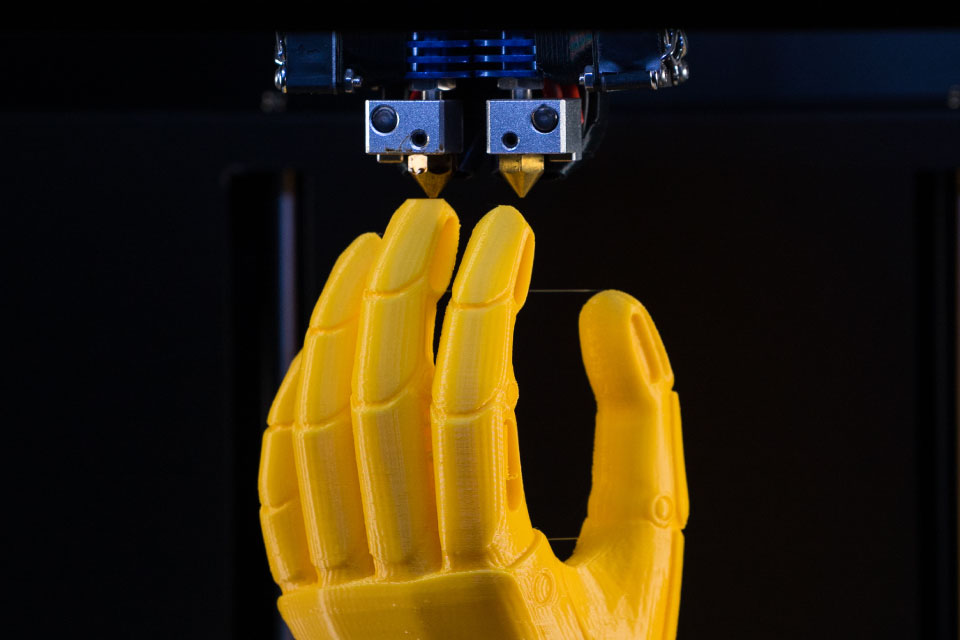

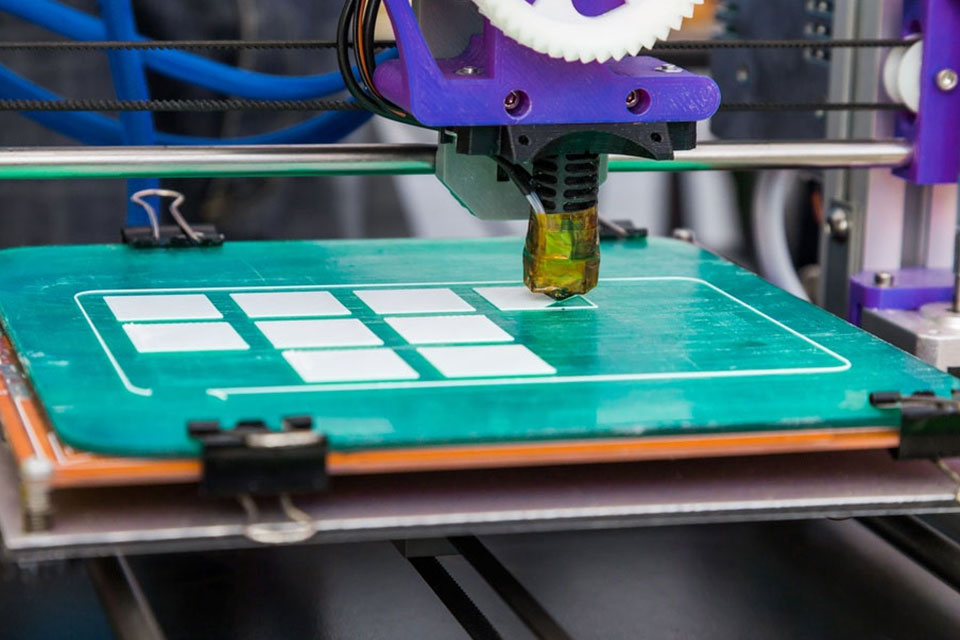

Additive Manufacturing

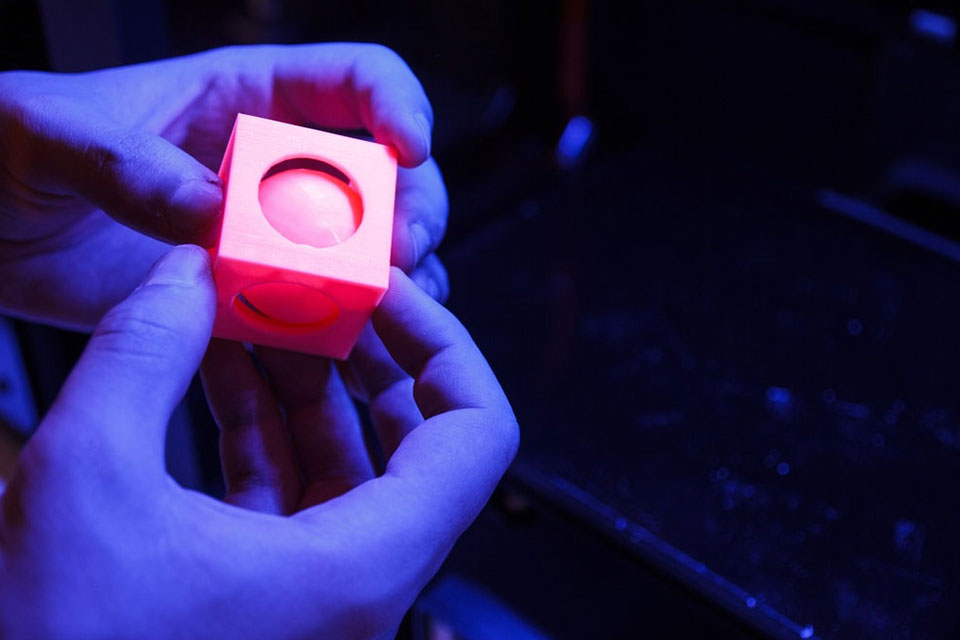

Additive manufacturing is the technology that unites an unlikely cohort— manufacturers, hobbyists, engineers, surgeons, and scientists; mass production capability for the manufacturer, the power to create for the hobbyist, the ability to bring ideas to […]

Additive Manufacturing Read More »