Additive manufacturing—or 3D printing—is 30 years old now. Today, it has found applications not just in industry but also in households because of how affordable it has become. As anything can be printed, 3D printing opened up unlimited opportunities for different manufacturing sectors, including apparel, medical, automotive, aviation, and even defense.

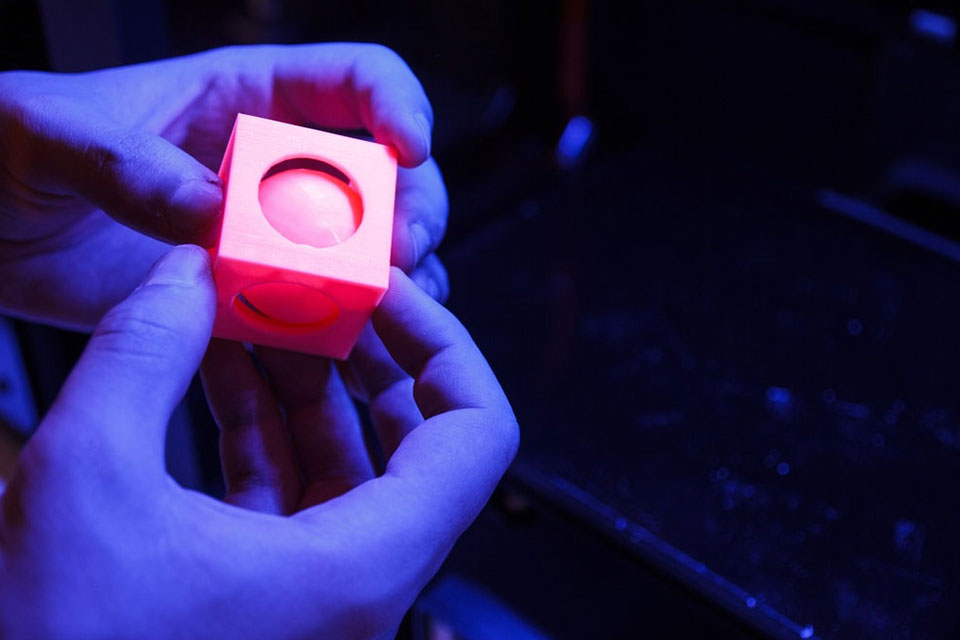

Despite these advances, there is a lot more that can be done with 3D printed materials to make them more flexible and useful. “4D printing”, as it’s commonly known, offers this flexibility and utility. 4D printing refers to 3D-printed objects that have an added dimension of “time”. Upon exposure to certain stimuli, these objects or materials transform and change shape over time.

4D printing takes the same technologies of 3D printing, but with a slight change. Printed in the fourth dimension, the materials or objects have new abilities and are able to assemble, change, or mutate over time when exposed to water, air, or a change in temperature.

Researchers are working on 4D printing materials and object formats. Eventually, the use of APIs (Application Programming Interfaces) will allow designers to pre-define characteristics of a material which will then be printed using chemically precise formulas to obtain specific attributes and functionality.

4D objects will act as shape-shifting smart materials with special characteristics. The products could change color to match their surroundings, or alter their shape as needed. For example, bridges could repair themselves as cracks form, and pipes could automatically adjust to the flow of liquid by expanding or contracting. Industries that can benefit from the use of adaptive, composite materials include manufacturing, packaging, and biomedical.

3D printing technology is steadily evolving with more complex printable materials and higher resolutions at larger scales. It is very likely that 4D printing will provide new ways to create highly functional, complex surfaces that would ultimately revolutionize engineering. 4D is showing enormous promise by making manufacturers think outside of the box. According to MarketsandMarkets, the total market is expected to reach $537.8 million by the year 2025.