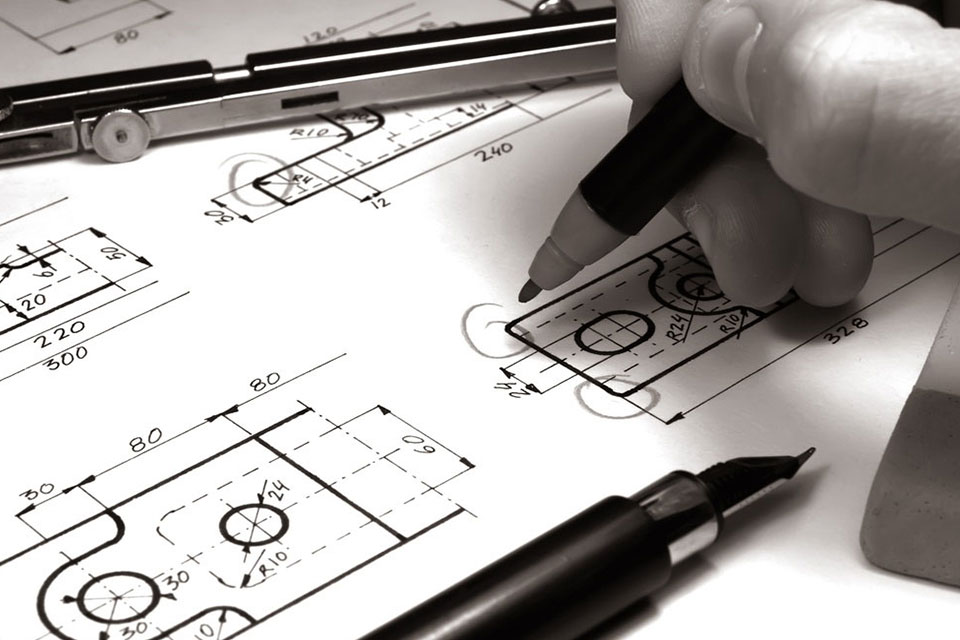

6 Mistakes to avoid in Geometric Dimensioning and Tolerancing

Every manufacturing company that uses drawings to develop a manufacturing plan and estimate the production time might calculate product costs incorrectly if there are errors in those drawings. Such errors may also extend the product cycle time by causing […]

6 Mistakes to avoid in Geometric Dimensioning and Tolerancing Read More »